The Role of Precision Plastic Components in Modern Electronics

Electronics and electrical systems have become the backbone of our modern lifestyle. From smart lighting in our homes to automation in industries, reliable performance depends heavily on the quality of the smallest components. Among these, plastic components play a vital role, offering not just insulation and protection but also design flexibility and durability. At Cancer Plastomech, we engineer these components with precision, ensuring that they meet the highest standards of performance and reliability.

Why Plastic Components Are Indispensable

Unlike metals, plastics offer unique advantages that make them essential in electronics:

- Electrical insulation – Prevents short circuits and leakage.

- Lightweight strength – Reduces device weight without compromising durability.

- Corrosion resistance – Ideal for long-term usage in challenging environments.

- Design flexibility – Allows complex shapes and custom designs.

- Cost efficiency – Enables large-scale production at competitive prices.

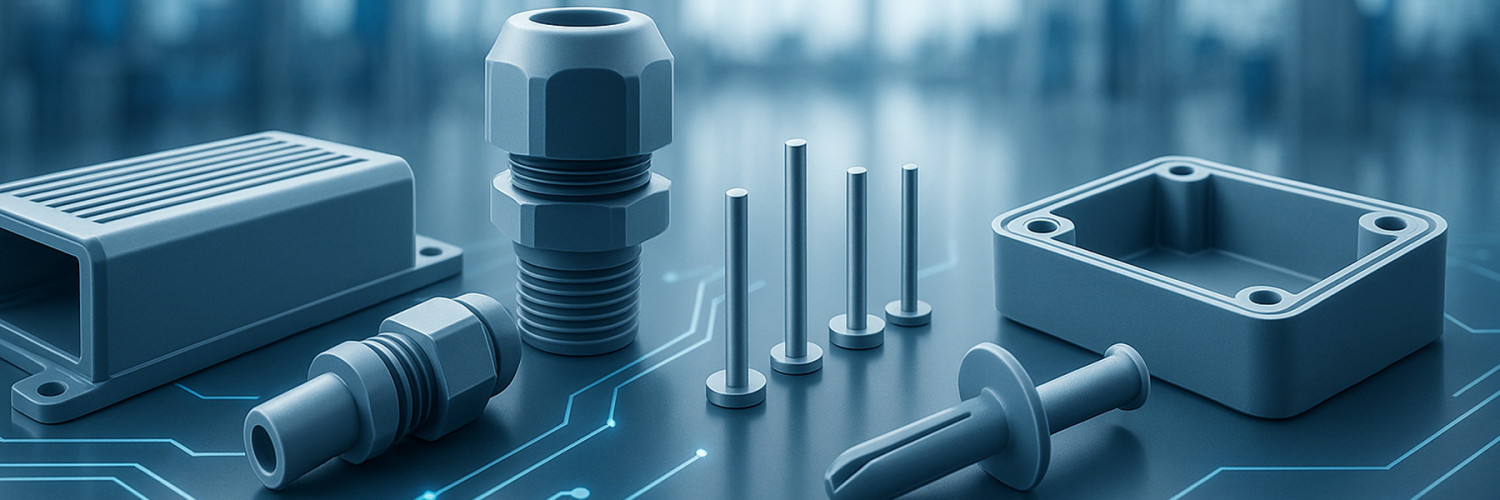

Key Plastic Components in Electronics

1. LED Driver Housings

LED systems demand housings that can handle heat, provide insulation, and ensure long life. Our LED driver housings are made from engineering plastics that combine thermal resistance with mechanical strength.

2. Power Adapter Housings

Adapters are used daily, from mobile chargers to industrial devices. Sturdy power adapter housings protect internal circuits from damage, heat, and external stress.

3. PCB Mounting Accessories

Printed Circuit Boards (PCBs) require precise mounting for error-free operation. Our pins, spacers, and accessories ensure secure placements, reducing the risk of failure in electronic assemblies.

4. Cable Glands and DIN Rail Clamps

In control panels and automation setups, cable glands and DIN rail clamps provide secure cable management and mounting solutions, ensuring safety and efficiency.

5. Washers, Rivets, and Fasteners

Small but critical, these parts provide mechanical stability, proper spacing, and insulation in electrical systems.

Industries That Depend on These Components

The applications of precision plastic parts are vast, serving industries like:

- LED lighting – Indoor, outdoor, and industrial fixtures.

- Consumer electronics – Everyday gadgets and home devices.

- Power electronics – Adapters, chargers, and stabilizers.

- Automation & Control Panels – For industrial safety and process efficiency.

- Renewable energy – Solar inverters and energy management systems.

The Cancer Plastomech Advantage

What sets us apart is our integrated approach to manufacturing:

- In-house tooling & mold making for total control over design.

- State-of-the-art injection molding machines for precision manufacturing.

- Strict quality control protocols for zero-defect production.

- Flexibility for small batches or bulk orders depending on client needs.

- Proven reliability with clients across multiple industries.

Future of Plastic Components in Electronics

The next generation of plastics will focus on sustainability and performance. Eco-friendly and recyclable engineering plastics, flame-retardant materials, and lightweight composites will drive innovation in the industry. At Cancer Plastomech, we are committed to adopting these advancements while continuing to deliver reliable solutions for our clients.

Conclusion

Precision plastic components may look small, but their impact is enormous. They ensure that devices work safely, efficiently, and reliably. By choosing Cancer Plastomech, manufacturers gain a trusted partner dedicated to quality, innovation, and customer success. Whether it’s OEM manufacturing, white label production, or contract manufacturing, we stand ready to deliver solutions that power modern electronics.